Description

Electric crucible furnaces for melting aluminum and alloys

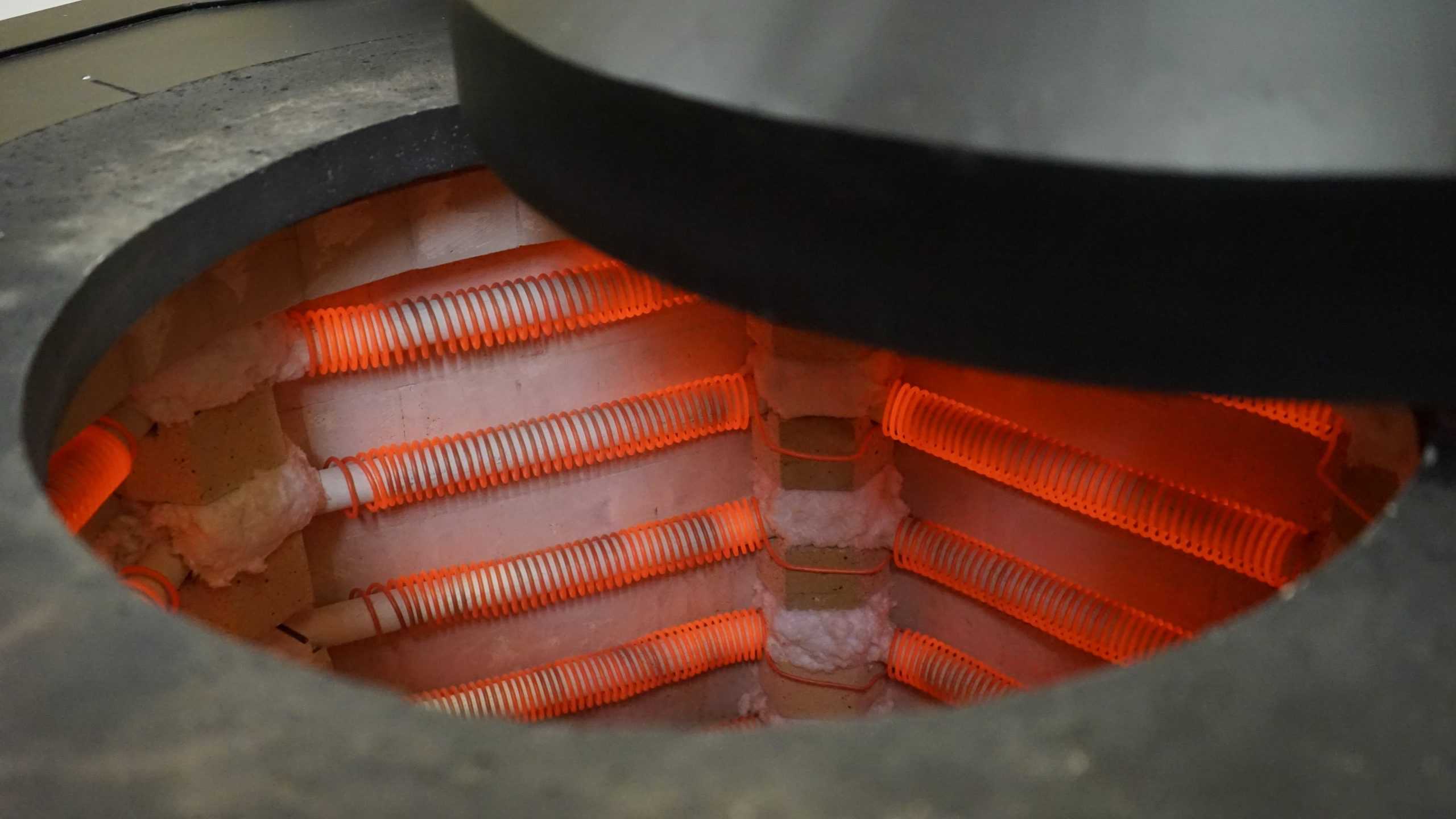

САТ – electric crucible furnaces for melting aluminum and alloys.

Crucibles of cast iron, heat-resistant steel, and graphite-chamotte are used for melting aluminum and alloys in furnaces. Furnaces can be stationary and rotary.

Advantages of crucible furnaces:

- simple design;

- operational reliability;

- ease of carrying out various technological operations (alloying, refining, degasification, modification);

- no contact with fuel combustion products, which ensures minimum burnout of alloy components and reduces the possibility of harmful gaseous impurities transitioning into the metal;

- possibility of using dispensers, manipulators, robots for casting metal in separate portions.

The furnaces are manufactured using modern insulation materials and are equipped with reliable monitoring and control systems.

Ordering specifics

All presented products are made to order. This allows the customer to make their own changes in the design of products and order the best option.

Video review of the electric crucible furnace for melting aluminum and alloys САТ-350

Specifications

| Parameters | САТ-0,05 | САТ–0,16 | САТ–0,25 |

|---|---|---|---|

| Capacity (calculated)*, kg/hour | 25 | 50 | 80 |

| Rated power, kW | 24 | 45 | 60 |

| Supply voltage, V | 3 х 380 | 3 х 380 | 3 х 380 |

| Capacity of aluminum melt, kg | 50 | 160 | 250 |

| Rated temperature in the working space, up to °С | 1000 | 1000 | 1000 |

| Maximum temperature of metal | 800 | 800 | 800 |

| Time of heating the furnace to the nominal temperature without charge, min | 180 | 180 | 180 |

| Automatic temperature control range, °C | 300-1000 | 300-1000 | 300-1000 |

| Type of crucible | ТГГ 200 | ТГГ 500 | ТГГ 750 or cast iron |

| Overall dimensions of furnace, mm, max, width (diameter) length height | 1100х1100х1050 | 1400х1400х1200 | 1550х1550х1350 |

| Furnace weight, kg, max | 1200 | 1500 | 2000 |

* The actual capacity is 60-80% of the design capacity, depending on the quality of the scrap.

Electric furnaces for aluminum melting can be made in inclined design and equipped with hydraulic or electromechanical lifting drive.