62 742 грн. – 75 162 грн.

Explanation of each symbol of the electric furnace СУОЛ-0,25.1/12,5 name:

ТУ У 28.2-30673694-002:2018

(Designation structure according to TS)

C – resistance – the type of heating;

У – tubular – a design feature;

О – oxidative – workspace environment;

Л – laboratory;

0,25 – diameter of the working space, dm;

1 – length of the working space, dm;

1250 – the nominal temperature in °C.

** The prices are valid subject to the signing of the product supply agreement in the version of the Manufacturer (seller). All prices include VAT.

Description

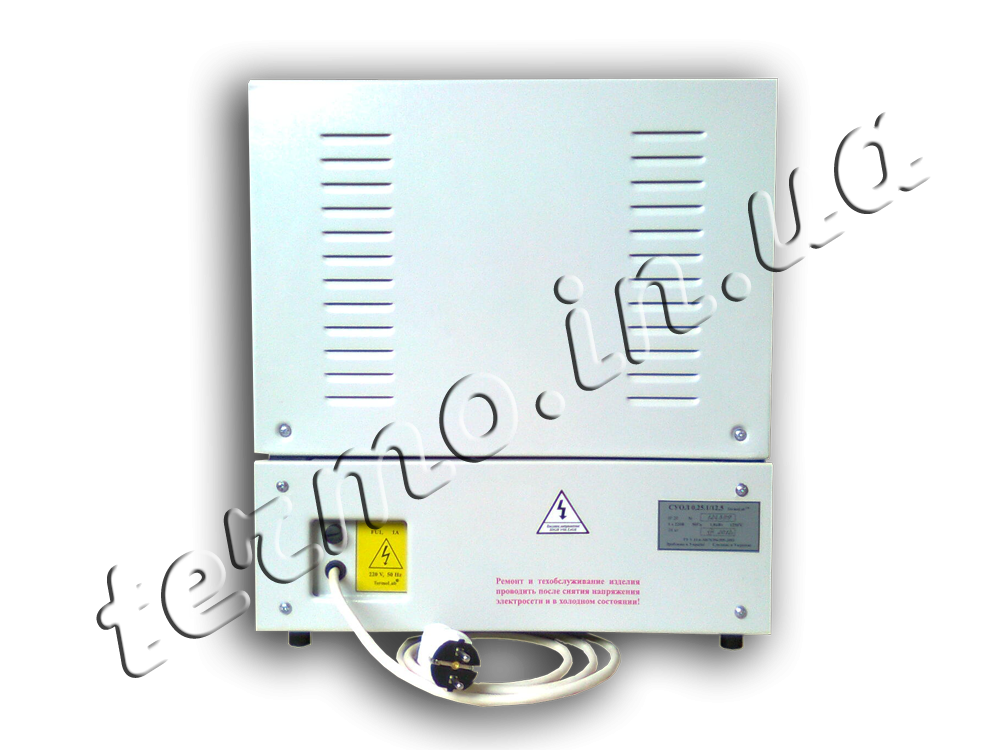

Tube electric furnace is designed for chemical analysis, calibration of thermocouples, heat treatment and determining the melting temperature of metals, alloys and other works at temperatures up to 1250 ° C in stationary conditions.

Temperature controller: the muffle furnace is equipped with microprocessor or programmable temperature controller. The microprocessor temperature controller has a power adjustment function, which is especially important when the furnace is operating at low temperatures. Controllers allow you to adjust the speed of heating – cooling, heating time.

Working chamber is made of ceramics, which makes the furnace particularly reliable in operation.

Chamber heating occurs from four sides, which makes it possible to have good temperature uniformity throughout the volume of the chamber.

The case of the furnace is made of sheet steel, powder coated on a special polymer coating line, which gives the surface an original look and durability in operation.

Thermal insulation the working chamber is made of highly efficient fibrous materials. For effective cooling of the furnace, a cooling fan is installed at the bottom.

Additionally the furnace can be equipped with a computer data acquisition system.

Specifications

| No. p / p | Name of technical specification | Unit | Value |

|---|---|---|---|

| 1. | Rated power, less than | kW | 1,8 |

| 2. | Supply voltage | V | 230 |

| 3. | AC frequency | Hz | 50 |

| 4. | Number of phases | 1 | |

| 5. | Rated working space temperature | °С | 1250 |

| 6. | Workspace environment | air | |

| 7. | Electric furnace warm-up time to nominal temperature* without charge, less than | min | 130 |

| 8. | The size of the working space, at least: diameter x length | mm | 25х100 |

| 9. | Overall dimensions, less than: width x length x height | mm | 560х460х580 |

| 10. | Weight, less than | kg | 25 |

* A steady thermal regime occurs after holding for at least 60 minutes at the set temperature, without the presence of external disturbances (opening doors, changing the temperature setting, changing the mains voltage, etc.)

Package contents

Electric furnace СУОЛ-0,25.1/12,5

Spare parts:

- fusible insert for 1A – 1 pc.

Operational documentation:

- passport for the electric furnace.

- certificate for temperature controller

Other models

| Name of technical specification | Т nom, °С | Power, kW / number of phases | Type of controller | Accuracy of temperature maintenance, °C | Working chamber | |

|---|---|---|---|---|---|---|

| Size, mm | Material | |||||

| СУОЛ-0,25.1/12,5 | 1250 | 1,8 / 1 | analog | ± 4 | Æ25х100 (Æ35х180) | ceramics |

| СУОЛ-0,4.4/12,5 | 1250 | 2,5 / 1 | microprocessor / programmable | ± 4 | Æ40х400 (Æ50х480) | ceramics |

| СУОЛ-0,6.6/12,5 | 1250 | 3,5 / 1 | microprocessor / programmable | ± 4 | Æ60х600 (Æ70х800) | ceramics |

| СУОЛ-0,8.6/12,5 | 1250 | 4,5/ 3 | microprocessor / programmable | ± 4 | Æ80х600 (Æ90х1000) | ceramics |

| СУОЛ-0,8.8/12,5 | 1250 | 4,5 / 1 | microprocessor / programmable | ± 4 | Æ80х800 | ceramics |

Warranty

The manufacturer provides a warranty for the product for 12 months. Warranty on the control unit – 18 months, on the thermoregulator series TermoPro® – 50 months.