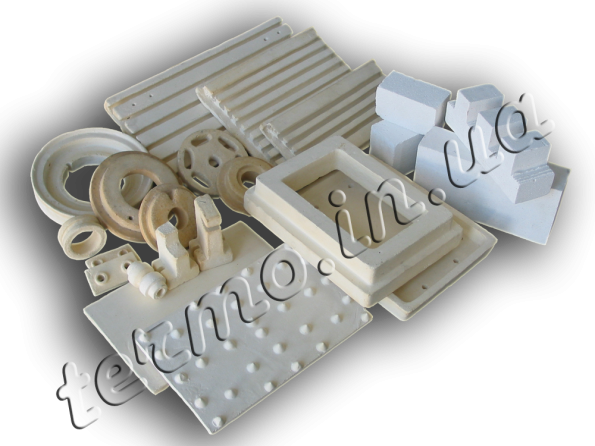

Shaped products from refractory ceramics

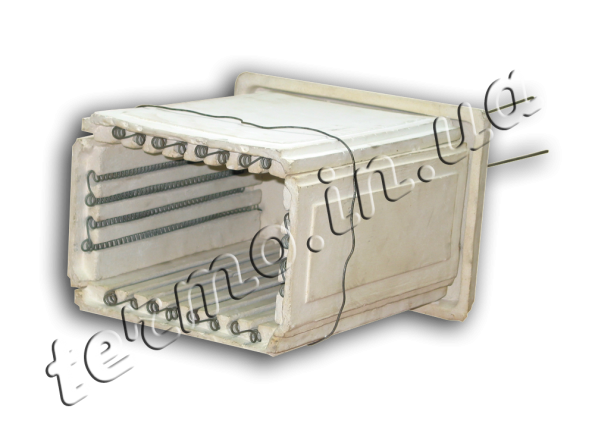

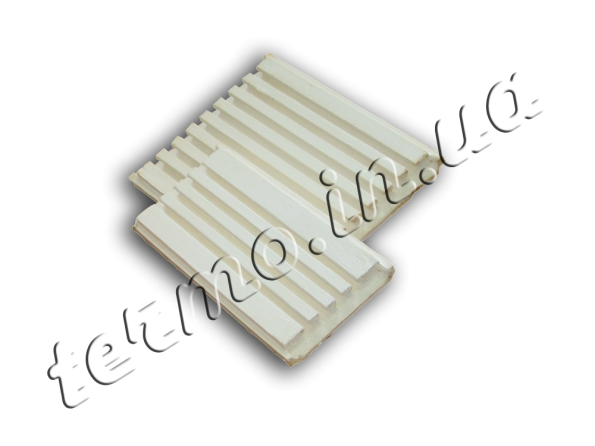

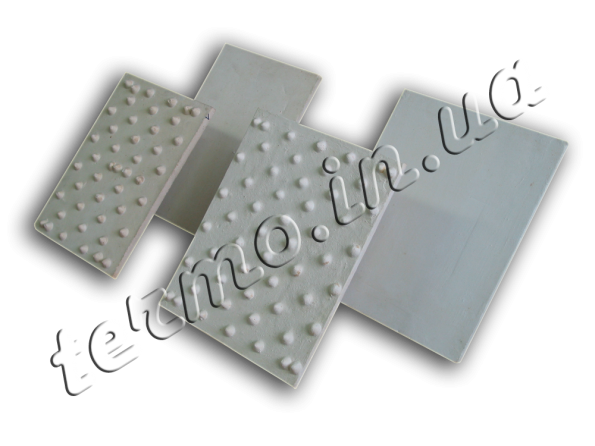

Cordierite ceramics are used in high-temperature industrial and laboratory furnaces as lining and hearth plates, for heater holders, heater outputs insulators and thermocouple inputs, etc. at temperatures up to 1300 °C.

The manufacture of cordierite ceramics is carried out by slip casting.

A distinctive feature of cordierite ceramics is that its coefficient of thermal expansion is several times lower than that of common oxide, high-alumina, and other types of ceramics.

Cordierite ceramics tolerate abrupt temperature changes and is a very heat-resistant material, have satisfactory resistance to the action of technological atmospheres, and do not interact with heaters made of high-resistance alloys (nichrome, kanthal) in the operating temperature range.

| № | Characteristics | Value |

|---|---|---|

| 1. | Apparent density, g/cm3, not less than | 1,95 - 2,3 |

| 2. | Ultimate compressive strength, MPa, not less than | 20 - 25 |

| 3. | Open porosity, no more | 28 |

| 4. | Thermal resistance (for samples) by the number of heat cycles, more | 50 |