Powder coating lines. Optional equipment

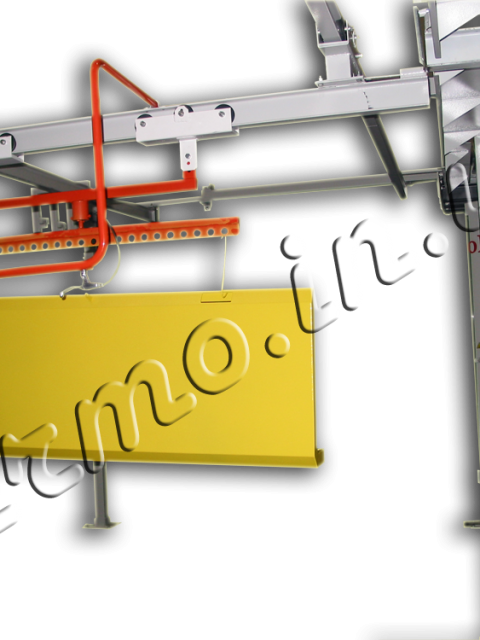

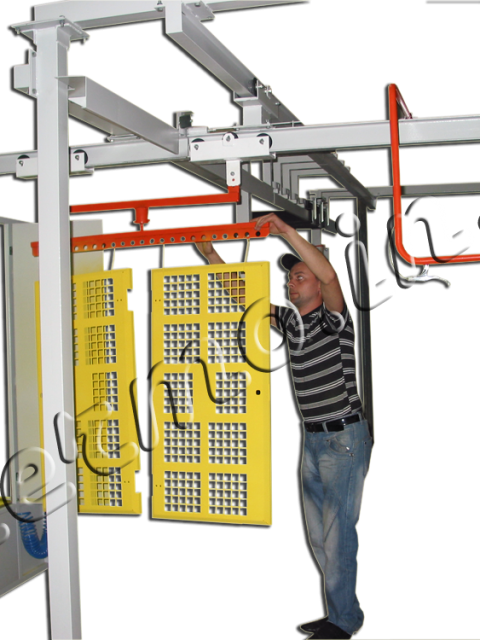

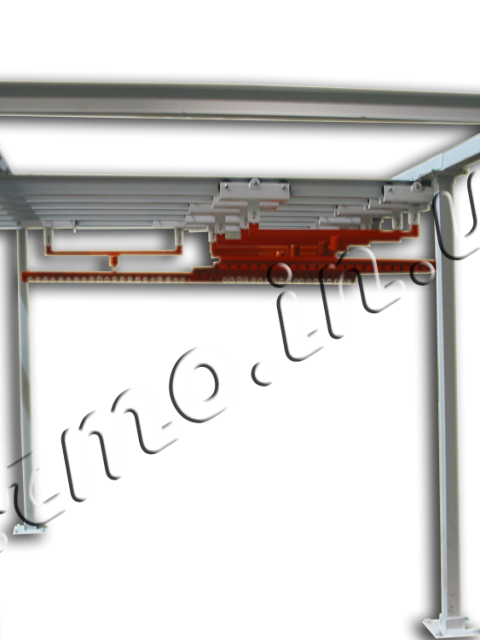

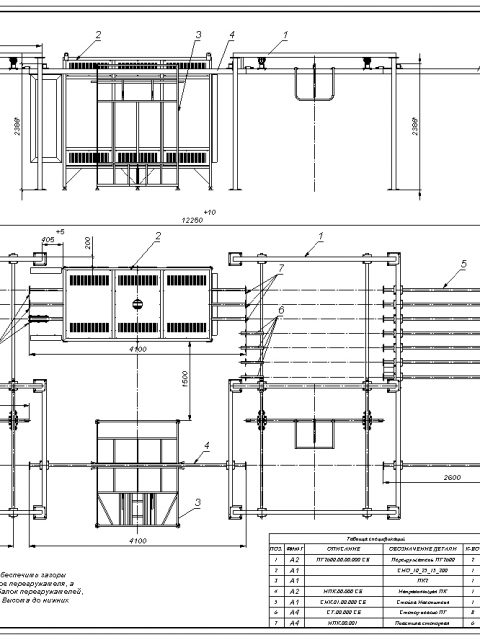

Transport systems are designed for transporting parts to be painted within the painting area. Transport systems are the ideal mechanization instruments for flexible production, allowing you to move loads of sprayed or hot products without the risk of damage. They are ready for further extensibility and could be integrated with automated devices for spraying powder coating. There is also an option of designing and manufacturing an electrically driven conveyor-type transport system.

Customers can request to supply only basic units and components.

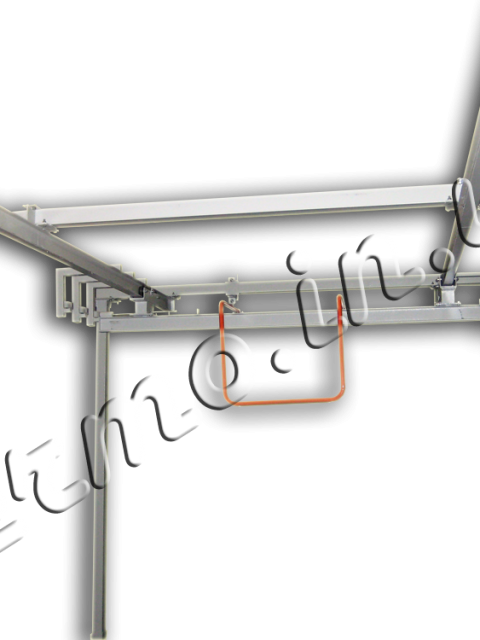

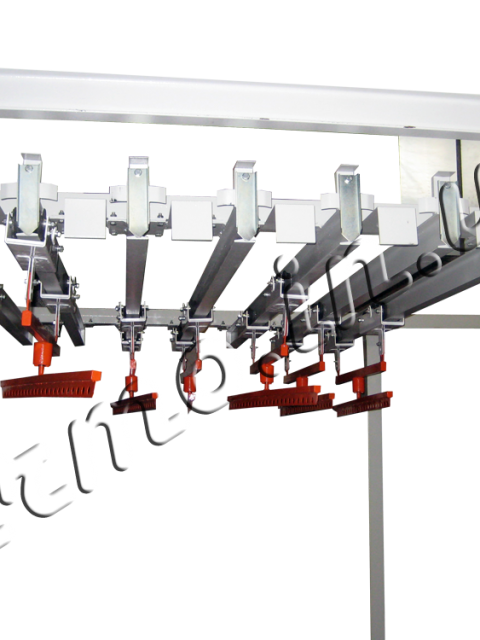

The transport system includes:

- Monorail suspended track;

- Suspension tie rods or supports;

- Mobile rotary hooks, reloaders.

The choice of equipment's type and its characteristics is made individually for each customer, depending on the size of the parts to be painted, their quantity, and the requirements for surface quality.

Surface preparation of steel parts may include operations:

- - degreasing + phosphating;

- - rinsing;

- - passivation;

- - drying.

Aluminum preparation before painting is one of the most time-consuming processes of pre-treatment of surfaces before painting and includes the following operations:

- - degreasing;

- - etching;

- - deoxidation;

- - chromating;

- - passivation.

Demineralized water preparation equipment.

To perform this operation, we supply pass-through washing units with systems for heating, mixing, and cleaning the solution, with automatic or semi-automatic spray nozzles, and special furnaces for drying products after washing.